Lasers & Optical Fibers Technologies

Lasers & Optical Fibers Technologies

Fiber Bragg Gratings (FBG) / Sensors systems

IDIL Fibres Optiques provides a wide range of Fiber Bragg Gratings (FBG sensors) designed according to customers’requirements.

Fiber Bragg Gratings (FBG) summary

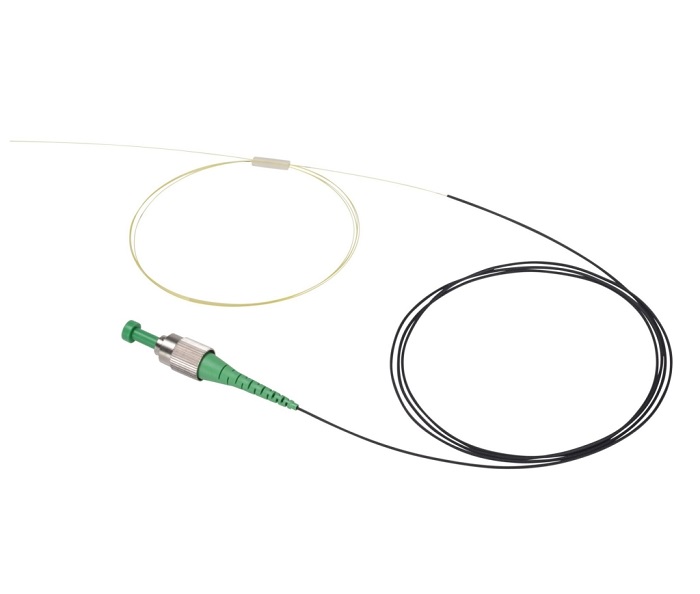

IDIL Fibres Optiques can work from single-mode, multi-mode and polarization maintaining fibers and supply every type of connectors. Furthermore we calculate and design the profile of FBG sensors. We also characterize and realize multiplexed FBG sensors (cf opposite) with several gratings on the same optical fiber (from one to about twenty) which can be close as a few millimeters or separated by a few kilometers. Finally we offer athermal, small size and weight packaging.

Our FBG sensors lead to numerous applications in the fields of optical sensors (temperature, strain, pressure…). Our technology is ideal for structural health monitoring of aircraft, buildings and dams; improving turbines and industrial equipment efficiency, detecting instabilities within tunnels and power plants, etc.

Contact us

for more informations

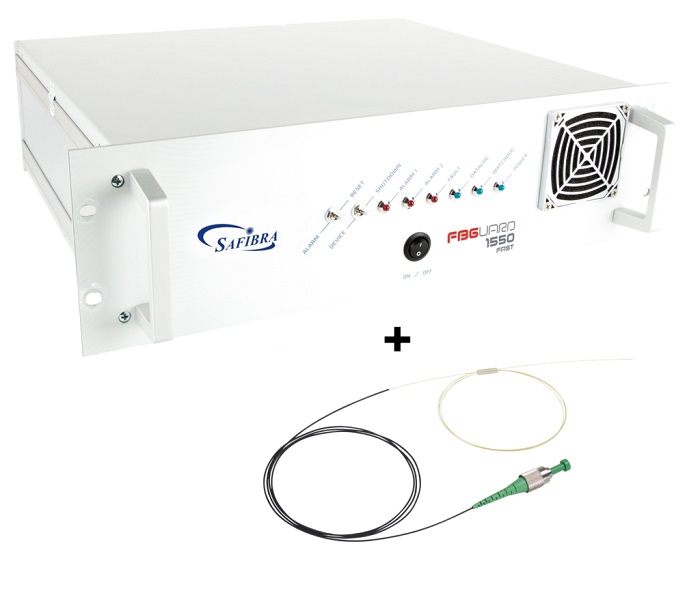

- Complete interrogation solution (interrogator, software interface and sensors)

- On-site installation, training and data acquisition

- SM, MM and PM fibers & every types of connectors

- Multiplexed FBG (typically up to 20)

- Multi-parameters: temperature, strain, pressure, acceleration, etc.

- Clean room manufacturing

- Structural health monitoring

- Industrial improvement

| FBG | |

|---|---|

| Wavelength | From 1 µm to 1.8 µm |

| Spectral width | From 100 pm to several tens nm |

| FBG packaging | Acrylate recoat, composite, embedded, miniature polyimide, surface and |

| weldable sensor | |

| Fiber type | SMF, MMF, PMF |

| Buffer | 250 µm; 900 µm; 2.8 mm |

| Transmission | From 1% to 99.9% |

| Connector | FC, LC, SC, SMA, ST, MU, E2000, other |

| Power handling | Up to 10 W |

| Calibration | Possible |

| Number of sensors | Single or multiple FBG (typical 20) |

| Operating temperature | Typical: From -10°C to 120°C (FOS-TA) |

| Higher: Please specify | |

Fiber Bragg Gratings technology consist of selecting only a very precise wavelength thanks to an optical mirror which was firstly photo imprinted by UV beam pattern into an optical fiber.

When the optical fiber is stressed or when its temperature is modified, the wavelength varies proportionally.